微孔成形之微放電複合製程技術開發

微放電結合電解拋光之微孔加工

![]() 本研究首先應用微細放電複合加工系統(如圖1所示),修整出所需形狀之工具電極,再製作各式微細孔洞。最後以電解拋光法,

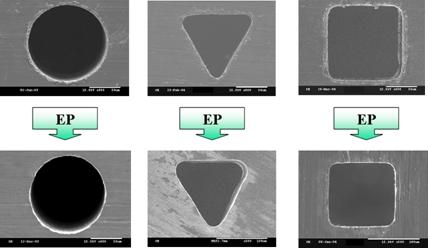

本研究首先應用微細放電複合加工系統(如圖1所示),修整出所需形狀之工具電極,再製作各式微細孔洞。最後以電解拋光法,

對微細孔的孔壁進行整平與亮化,去除放電加工後所產生的放電痕與再鑄層,達到光亮、平滑的孔壁表面。經由電解拋光加工製

程,可得到平直輪廓外形(如圖2所示)及精細、高品質的加工表面(如圖3與圖4所示),以滿足相關領域的業界對高品質微細孔的需

求。

圖1 複合加工機構設備圖

(a) 放電加工後 (b) 電解拋光後

圖2 電解拋光前後微孔垂直狀態改善示意圖

圖3 微孔入口經由電解拋光後之改善狀態

|

|

|

|

|

|

|

Before electropolishing (2.11 μm Rmax) |

After electropolishing (0.69 μm Rmax) |

圖4 電解拋光前後微孔表面與粗糙度之改善狀態

微放電結合超音波振動之微孔加工

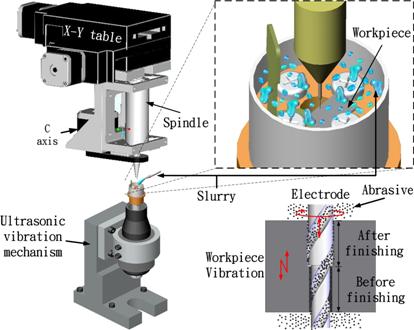

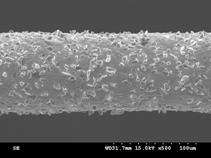

![]() 以微放電加工配合超音波振動設備(如圖5所示)的複合精修製程針對微孔進行精度改善。複合精修製程大致分為二階段,第一階

以微放電加工配合超音波振動設備(如圖5所示)的複合精修製程針對微孔進行精度改善。複合精修製程大致分為二階段,第一階

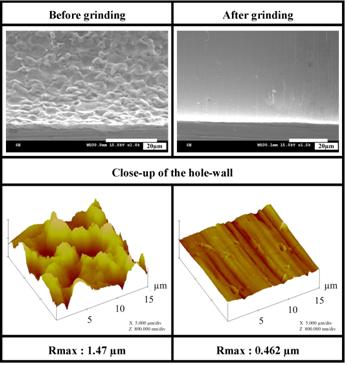

段為微孔成型,第二階段則利用超音波振動研磨去除孔壁表面放電坑,使得微孔獲得較佳的改善效果(如圖6與圖7所示)。

圖5 微放電複合超音波振動精修加工微孔示意圖

微放電結合Ni-SiC複合電鍍之微孔加工技術開發

![]() 為改善微孔表面粗糙度與孔洞的真直度,本研究應用複合電鍍沉積機制(如圖8所示)製作出表面磨粒分布均勻之微型研磨工具(如圖

為改善微孔表面粗糙度與孔洞的真直度,本研究應用複合電鍍沉積機制(如圖8所示)製作出表面磨粒分布均勻之微型研磨工具(如圖

9所示),經由精密研磨加工,可獲得高品質,符合工業所需的微孔(如圖10所示)。

Reference to Celis et al.

圖8 Celis五階段沉積機制

圖9 Ni-SiC複合電鍍後之微型工具表面狀態

圖10 孔壁研磨前後之表面改善

放電結合Ni-Diamond複合電鍍製作微型球狀研磨工具

(發明專利申請中)

![]() 本研究主要目的為開發適用於精微模具或微細凹型球面模穴等微結構精微加工用之Ni-Diamond微型球狀研磨工具。此製程如圖11

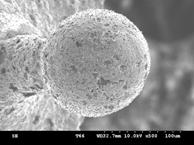

本研究主要目的為開發適用於精微模具或微細凹型球面模穴等微結構精微加工用之Ni-Diamond微型球狀研磨工具。此製程如圖11

所示,首先利用微放電加工出所需之細微電極棒,再對其端部放電形成微球,最後再經Ni-Diamond複合電鍍法製作出表面均勻分

布且形狀精度頗佳之微型球狀研磨工具,如圖12所示。

(a) 微型球狀研磨工具 (b) 表面局部放大

圖12 微型球狀工具之表面形貌圖

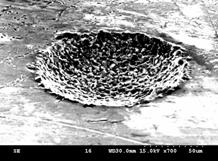

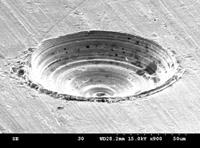

![]() 圖13為此研磨工具使用放電加工法所製作的微凹型球面模穴。由於此模穴充滿放電加工痕,造成凹型球面精度極度不佳,並不符

圖13為此研磨工具使用放電加工法所製作的微凹型球面模穴。由於此模穴充滿放電加工痕,造成凹型球面精度極度不佳,並不符

合精密加工所需。圖14則是使用該微型球狀研磨工具進行研磨加工時所獲得之模穴形狀。圖中顯示其可有效加工出一微凹型球面

模穴,但由於該方法加工時採用單軸旋轉加工,因此模穴表面易形成同心圓狀研磨痕跡,且模穴中央亦有中心死點存在。為了改

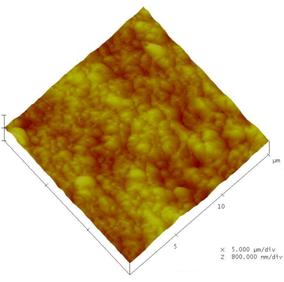

善此一問題,進一步採用游離磨粒搭配微型球狀研磨工具進行精修加工。實驗結果顯示該加工法可達到一極佳表面,如圖15所

示。其加工後之表面粗糙度由原子力顯微鏡檢測得到Rmax為0.353μm,如圖16所示。

(a) 微型球狀工具加工後形貎 (b) 微凹型球面模穴形貎

圖14 微型球狀工具直接研磨之成果圖

圖16 微凹型球面磨穴精修研磨加工後之AFM圖(Rmax:0.353 μm)